About Us

Experience the pinnacle of PCB manufacturing and Cable/harness assembly excellence with OnShore Assembly. Our 40 year commitment to precision, innovation, and quality ensures the seamless realization of your electronic designs. From concept to completion, our comprehensive services deliver exceptional solutions that drive technological advancements and exceed your highest expectations.

Services

-

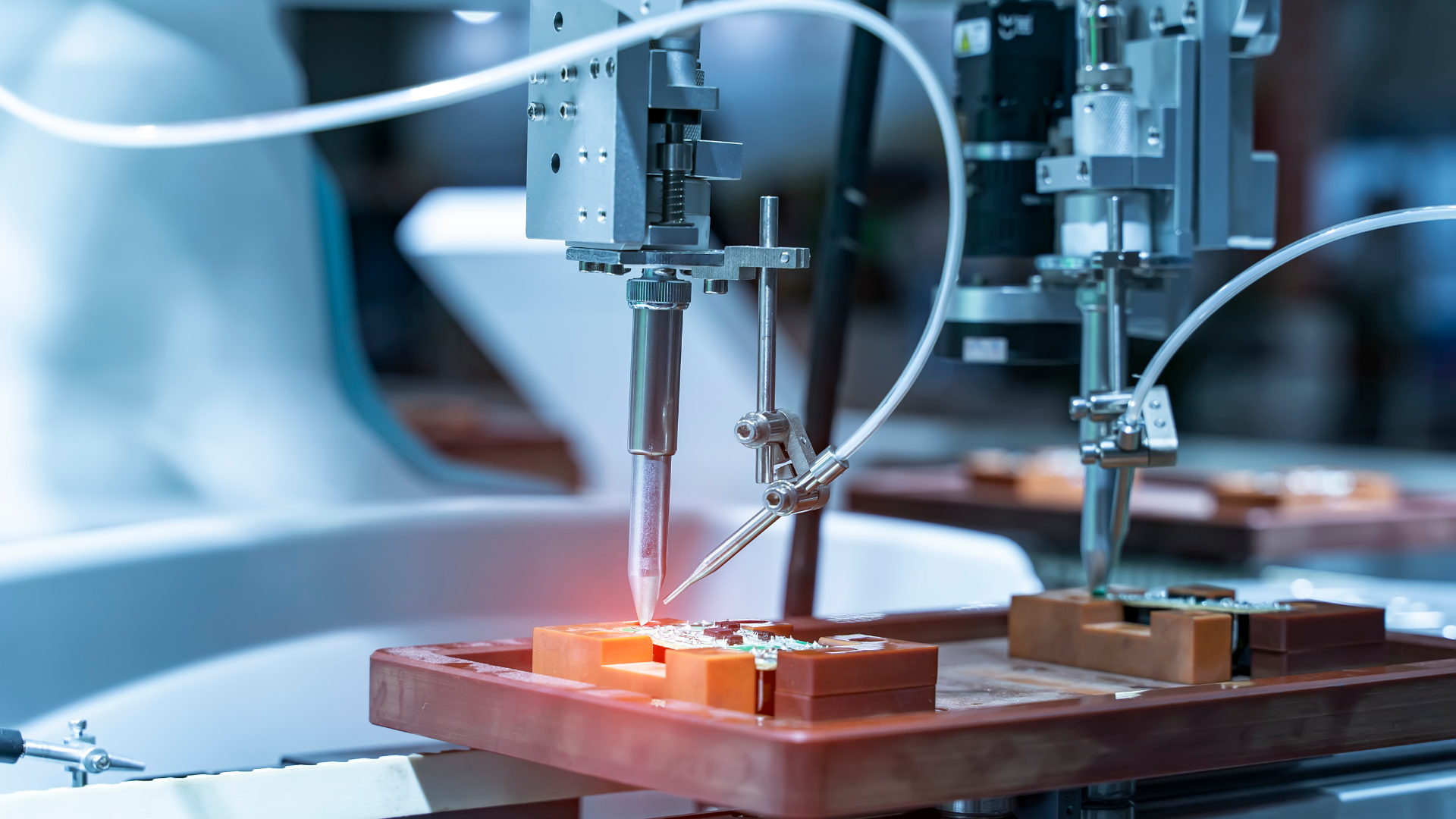

At OnShore Assembly, we specialize in PCB assembly, utilizing both Surface Mount Technology (SMT) and Through Hole methods. With SMT, we expertly place and solder surface-mounted components directly onto the PCB, enabling compact designs and increased component densities. For applications that require additional mechanical strength and reliability, we employ the Through Hole technique, inserting component leads through pre-drilled holes on the PCB and soldering them on the opposite side. Our experienced team carefully selects the appropriate method based on the unique design requirements and manufacturing considerations of each PCB assembly project, ensuring optimal performance and quality.

-

At OnShore Assembly, we specialize in seamlessly transitioning from prototypes to production runs for electronic products. Prototypes are crucial for validating design and functionality, and our expert team meticulously manufactures and tests them to refine the product. Once the prototype is validated, we initiate production runs, implementing established manufacturing processes and quality control measures. Our focus on careful planning, coordination, and optimization ensures a streamlined and efficient manufacturing process, delivering consistent quality and meeting production targets. We pride ourselves on our ability to smoothly transition from prototypes to full-scale production, helping our clients confidently bring their innovative ideas to market.

-

At OnShore Assembly, we excel in managing high mix low volume (HMLV) to production runs, providing tailored manufacturing solutions for a wide range of products with varying quantities. Our expertise lies in efficiently handling diverse product configurations, components, and assembly processes within a complex production environment. With efficient scheduling, flexible manufacturing capabilities, and streamlined logistics, we meet the unique demands of each product variant while upholding stringent quality standards and ensuring timely delivery. As we transition from HMLV to production runs, we seamlessly scale up the manufacturing process while maintaining the flexibility and agility to effectively accommodate the diverse product mix. We aim to deliver superior manufacturing services that cater to your needs, whether a high mix, low volume, or full-scale production requirement.

-

At OnShore Assembly, we specialize in wave soldering, a reliable soldering technique used in electronics manufacturing to join components to printed circuit boards (PCBs). Our wave soldering processes ensure efficient and high-quality soldering of through-hole components, enabling large-scale production with consistent results. We are committed to environmental sustainability and compliance with the RoHS directive, which restricts hazardous substances in electronic products. Therefore, our wave soldering processes strictly adhere to the use of lead-free solder, ensuring both environmental safety and the well-being of individuals. Additionally, we understand the diverse needs of our clients and applications, which is why we offer the option of leaded solder to accommodate specific requirements and compatibility considerations. Our focus is on delivering exceptional quality, upholding environmental responsibility, and meeting industry standards throughout the electronics manufacturing process.

-

At OnShore Assembly, we specialize in RoHS-compliant assembly, adhering to the strict guidelines set forth by the RoHS directive to manufacture electronic products that are environmentally safe and compliant with regulations. Our skilled technicians utilize hand soldering techniques, employing soldering irons or guns, to ensure precise and flexible soldering for intricate tasks, repairs, and modifications on printed circuit boards (PCBs). By combining RoHS-compliant assembly practices with the expertise of our technicians in hand soldering, we deliver exceptional electronic assemblies that meet regulatory requirements and accommodate customization and precise soldering specifications. Our commitment to RoHS compliance and meticulous hand soldering enables us to provide high-quality products that exceed industry standards and surpass customer expectations.

-

At OnShore Assembly, we employ the nitrogen atmosphere reflow oven process, a specialized technique that ensures optimal soldering results in electronic manufacturing. By creating a controlled nitrogen environment, we minimize oxidation during the reflow process, leading to enhanced solder joint quality, reduced defects, and improved overall reliability of the assembled circuit boards. The stable and inert nitrogen atmosphere promotes consistent heating and cooling, improving solder wetting and reducing thermal stress on the components. This advanced reflow process is particularly advantageous for complex and sensitive electronic assemblies that require precise temperature profiles and superior soldering performance. At OnShore Assembly, we leverage our nitrogen atmosphere reflow oven expertise to deliver high-quality, reliable electronic manufacturing solutions for your specific needs.

-

At OnShore Assembly, we specialize in mechanical assembly as a crucial aspect of our comprehensive manufacturing services. Our skilled technicians possess extensive expertise in fastening, joining, aligning, and mounting mechanical components to bring together the final product. With meticulous attention to detail, they follow precise assembly instructions and engineering specifications, utilizing various tools and techniques to ensure the accurate and secure assembly of parts. Through our mechanical assembly process, we strive to create products that are functional and reliable, meeting stringent quality standards and exceeding customer expectations. Our commitment to mechanical assembly excellence ensures that the result is a high-quality product that meets your specific requirements.

-

At OnShore Assembly, we specialize in electro-mechanical assembly, where we seamlessly integrate electrical and mechanical components to create sophisticated systems that deliver complex functionalities. Our skilled technicians, with electrical and mechanical engineering expertise, work diligently to assemble, wire, and integrate various components, including circuit boards, sensors, actuators, connectors, motors, gears, and structural elements. With meticulous attention to detail, we ensure precise alignment, secure connections, and flawless functionality of these components, resulting in high-quality electro-mechanical assemblies. Our experience spans diverse industries, including robotics, automation, aerospace, and medical devices, where the seamless coordination between electrical and mechanical systems is paramount to achieving optimal performance. Trust OnShore Assembly for reliable and efficient electro-mechanical assembly solutions tailored to your specific needs.

-

At OnShore Assembly, we specialize in chassis assembly, where we expertly construct and integrate the framework or enclosure that houses electronic and mechanical components. Our skilled team meticulously mounts and secures components, connects wires and cables, and installs panels and covers to create a robust and reliable chassis. Once the assembly is complete, we conduct rigorous testing to verify proper functionality, structural integrity, and adherence to strict quality standards. Our comprehensive testing includes checks for electrical connectivity, mechanical stability, thermal management, and overall system performance. Chassis assembly and testing are crucial steps in ensuring the reliability and performance of electronic systems, particularly in industries such as telecommunications, industrial automation, and server infrastructure. With our expertise and attention to detail, we deliver top-quality chassis assembly solutions that meet your specific requirements.

-

At OnShore Assembly, we specialize in custom cable and harness assembly, providing expert fabrication and assembly of specialized wiring solutions for various industries. Our skilled technicians are proficient in precise wire cutting, stripping, crimping, soldering, and cable routing techniques, ensuring that each cable and harness meets the specific length, shape, and routing requirements. Working closely with our engineers, we meticulously follow detailed wiring diagrams and specifications to deliver high-quality, reliable wiring solutions. Every product undergoes rigorous testing to guarantee proper connectivity, signal integrity, and durability. With our expertise in custom cable and harness assembly, we serve industries such as automotive, aerospace, telecommunications, and medical devices, where robust and well-organized wiring systems are crucial for optimal system performance. Trust OnShore Assembly to deliver exceptional custom cable and harness solutions tailored to your specific requirements.

-

At OnShore Assembly, we offer both consignment and turnkey programs to cater to the diverse needs of our customers in the manufacturing industry. With our consignment program, you have the option to provide the necessary materials and components, giving you control over inventory management while reducing upfront costs. Our skilled team will assemble the product using the provided parts to ensure high-quality results. Alternatively, our turnkey program takes the burden off your shoulders as we handle the entire procurement and supply process. We source and procure all the required materials and components, ensuring a seamless and hassle-free experience for you. Whether you prefer consignment or turnkey, we customize our approach to align with your cost, control, and logistics preferences. With OnShore Assembly, you can trust us to efficiently manage your supply chain and deliver exceptional manufacturing services.

-

At OnShore Assembly, we prioritize efficient inventory management through our stock room MRP (Material Requirements Planning) control and kitting processes. Our advanced software systems enable us to track and manage inventory levels, monitor demand, and generate precise purchase or production orders to maintain optimal stock levels. By implementing MRP control, we prevent stockouts and excess inventory, ensuring that materials are readily available for production when needed. Additionally, our kitting process involves assembling and packaging specific components or parts into convenient kits, streamlining the manufacturing process and reducing handling and setup time. These integrated stock room MRP control and kitting practices enhance productivity, shorten lead times, and ensure accurate inventory management, contributing to overall operational efficiency and customer satisfaction.

-

Item At OnShore Assembly, we prioritize quality control through our advanced X-ray inspection capability. With this technology, we conduct non-destructive testing of printed circuit boards (PCBs) and assembled electronic components to ensure product reliability. Our X-ray inspection process allows us to detect critical issues such as solder joint integrity, component alignment, and hidden defects like shorts, opens, or voids. By providing a comprehensive view of the internal structures, we can analyze and identify potential issues with precision. With our X-ray inspection capability, we maintain high-quality standards, enhance product performance, and deliver reliable and defect-free electronic assemblies, ensuring the utmost satisfaction of our customers.description

-

At OnShore Assembly, we prioritize the reduction of process defects as a fundamental aspect of our manufacturing operations. Through the implementation of robust quality control measures, meticulous inspection protocols, and continuous process improvement initiatives, we aim to identify and address potential defects at their root causes. Our proactive approach enables us to streamline operations, minimize rework or scrap, and reduce associated costs. With comprehensive training programs, standardized operating procedures, and vigilant monitoring, we optimize our processes to enhance product reliability and achieve higher levels of customer satisfaction. By strongly emphasizing defect reduction, we enhance our operational efficiency, increase profitability, and maintain a competitive edge in the market.

-

The quality control of PCB assembly begins with a thorough inspection of incoming materials, such as components, PCBs, and solder paste. Each component undergoes meticulous verification to ensure it meets the specified requirements. Prior to assembly, solder paste is checked for consistency and proper alignment using automated inspection systems, such as SPI (Solder Paste Inspection) machines. During the assembly process, advanced automated optical inspection (AOI) systems are employed to inspect the placement and soldering of components. These systems use high-resolution cameras to detect any deviations, misalignments, or defects.

Additionally, in-circuit testing (ICT) is available to evaluate the electrical functionality of the assembled PCB. Functional testing, including power-up testing and boundary scan testing, is performed to validate the overall performance and functionality of the PCB. Environmental testing is carried out to ensure that the PCBs can withstand specified temperature, humidity, and vibration conditions. A comprehensive documentation process is maintained throughout, including recording test results, tracking component sources, and maintaining traceability for future reference. The quality control process concludes with packaging and shipping of the verified and approved PCB assemblies to customers, providing them with reliable, high-quality electronic components for their applications.

Certifications

ISO 9001: 2015 Certified

IPC-A-610 Trainer On Site

IPC-WHMA-A-620 Compliant

J-STD-001 Trainer On Site