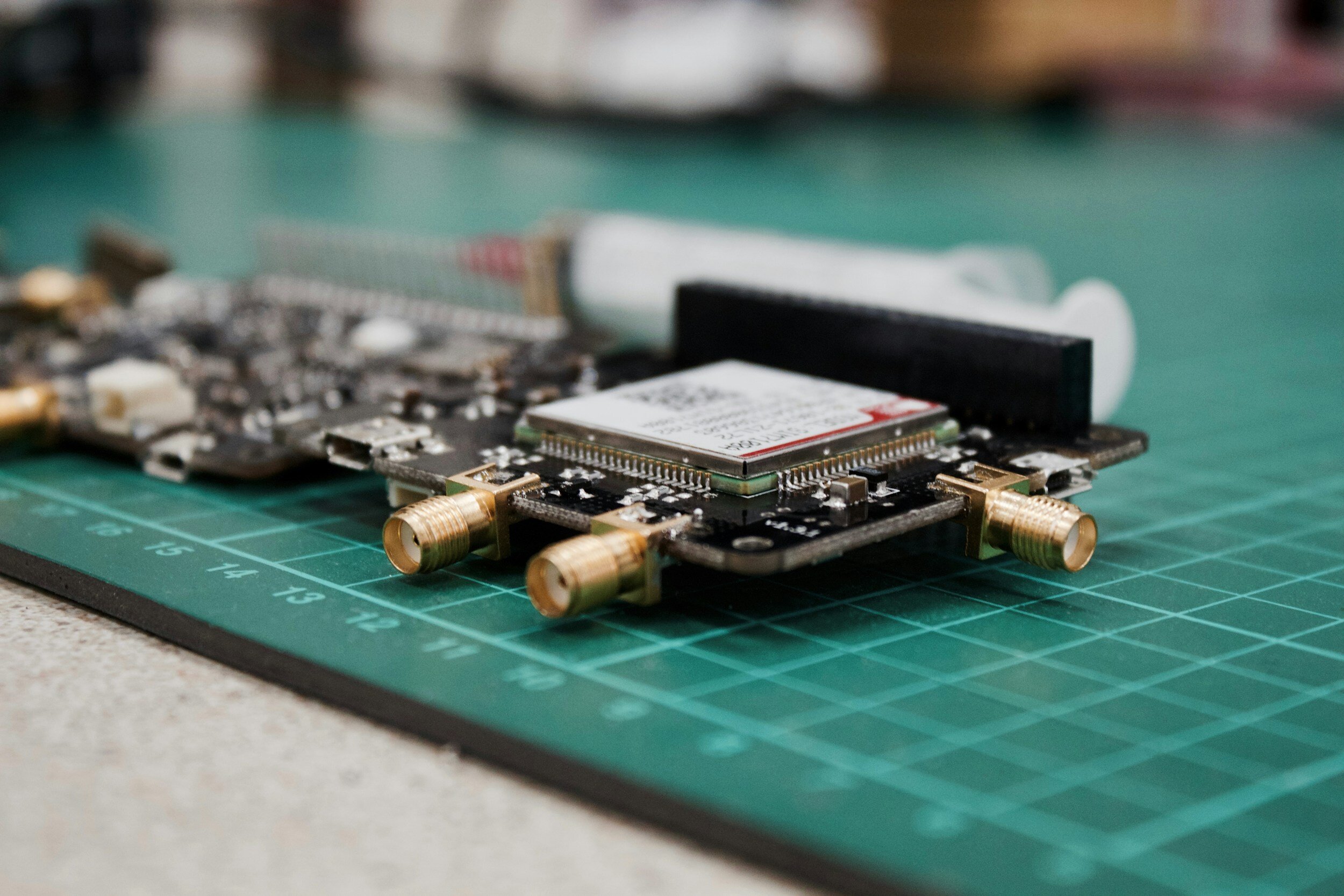

PCB Assembly

At OnShore Assembly, we specialize in delivering unparalleled services in Printed Circuit Board (PCB) Assembly. Our advanced PCB services adhere to the highest industry standards, including RoHS compliance to meet environmental regulations. From single-sided to complex multi-layer boards, our capabilities ensure that your PCB requirements are met with precision and efficiency.

Cutting Edge Technology

Our state-of-the-art facilities are equipped with the latest technology to handle the intricacies of PCB Assembly. From prototype development to high-volume production, we ensure the highest quality standards.

Experienced Team

Our skilled and experienced team of technicians and engineers brings a wealth of knowledge to every PCB assembly project. We prioritize attention to detail and rigorous quality control measures to guarantee the reliability and functionality of the final product.

Customized Solutions

At OnShore Assembly, we understand that each project is unique. Our flexible approach allows us to tailor our PCB assembly services to your specific requirements, ensuring that your electronic designs are brought to life with precision and efficiency.

Capabilities

Our advanced PCB services adhere to the highest industry standards, including RoHS compliance to meet environmental regulations. With expertise in various board types and layers, we provide a technology overview that encompasses the latest advancements in the field. From single-sided to complex multi-layer boards, our capabilities ensure that your PCB requirements are met with precision and efficiency.

-

Ability to produce single-sided, double-sided, or multi-layer PCBs.

Expertise in various substrate materials, including FR-4 and specialized materials.

Processes for etching, drilling, and layering to create precise circuit patterns.

-

Utilization of automated pick-and-place machines for precise placement of surface mount components.

Application of solder paste and reflow soldering for creating electrical connections.

-

Manual or automated insertion and soldering of through-hole components.

Wave soldering or selective soldering processes for through-hole components.

-

Integration of both surface mount and through-hole components on the same PCB.

-

Procurement of electronic components from reliable suppliers.

Verification of component authenticity, compliance, and quality.

-

Rapid prototyping services for accelerated product development cycles.

Fast turnaround times for small quantities of prototype boards.

-

Efficient assembly of electronic components for medium to small-sized production quantities.

-

Visual inspection to ensure component placement accuracy and solder joint quality.

In-circuit testing (ICT) or functional testing to verify the functionality of assembled boards.

X-ray inspection for hidden defects or solder joint quality in complex assemblies.

-

Application of conformal coatings to protect PCBs from environmental factors.

Encapsulation of sensitive components for added protection against physical and environmental stress.

-

Assembly of complete electronic systems, including PCBs, wiring, and enclosures.

Integration of additional components like connectors, switches, and displays.

-

Collaboration with design teams to optimize PCB layouts for efficient manufacturing.

Providing recommendations to enhance the testability of the final product.

-

Adherence to industry standards and quality control processes.

Certification compliance (e.g., ISO 9001) for quality management systems.

Equipment

Performing Printed Circuit Board (PCB) assembly services requires specialized equipment to handle various stages of the assembly process. The specific equipment needed may vary based on the complexity of the assembly, the size of the production run, and the technology used. Having a well-equipped facility ensures efficient and high-quality PCB assembly services. OnShore’s specialized equipment includes:

-

Automated machines that pick up electronic components from reels or trays and precisely place them onto the PCB.

-

Equipment used to accurately deposit solder paste onto the PCB, ensuring proper adhesion of surface mount components during the reflow soldering process.

-

Ovens that heat the PCB to melt the solder paste, creating secure solder joints between components and the board.

-

Used for through-hole component assembly, these machines pass PCBs over a molten solder wave to solder through-hole components.

-

Provides selective application of solder to specific areas, suitable for assemblies with both surface mount and through-hole components.

-

Equipment for precisely applying solder paste onto the PCB through a stencil, ensuring accurate deposition before component placement.

-

Systems that use cameras and image recognition software to inspect the quality of solder joints and component placement on assembled PCBs.

-

Used for non-destructive inspection of hidden solder joints and components, particularly useful for complex assemblies with multiple layers.

-

Equipment for applying a protective conformal coating to the PCB to safeguard it against environmental factors like moisture, dust, and chemicals.

-

Machines that separate individual PCBs from a panel after assembly.

-

Custom fixtures designed to facilitate in-circuit testing (ICT) or functional testing of assembled PCBs.

-

Tools for both manual and automated assembly, including soldering irons, hand tools, and automated screwdrivers for assembling through-hole components or other manual tasks.

-

Equipment used to clean solder paste stencils for reuse in the solder paste printing process.

-

Antistatic workstations, flooring, and personal protective equipment to prevent electrostatic discharge during the assembly process.

-

For programming microcontrollers, memories, or other programmable components on the PCB.

Project Profiles

Quick Turn Prototypes

In the dynamic landscape of electronic manufacturing, quick turn prototypes play a pivotal role in expediting product development cycles. From component sourcing to surface mount technology (SMT) and through-hole assembly, these services are orchestrated with precision, ensuring that the prototypes meet the highest quality standards while adhering to the specific design requirements.

Medium to Small Size Production

For clients requiring a scalable and flexible approach to manufacturing beyond the prototype stage, OnShore provides tailored solutions. Efficient assembly of electronic components onto printed circuit boards allow for cost-effective and agile manufacturing solutions.